1/182ページ

Download(13.5Mb)

CAT1600E

Document Information

| Document Title | Linear Motion Rolling Guide BLUE |

|---|---|

| Document Type | Product Catalog |

| File size | 13.5Mb |

| Category | |

| Company | Nippon Thompson Co., Ltd. (Documents List) |

Documents related to this company

Document Contents

Page1

Cover

LINELAIRN EMAORT MIOONT RIOONL LRIONLGL GINUGID GEU BIDLUEE BLUE CAT-16C0A0TE-1600E

LLININEEAARR W WAAYYSS

Recognizing Rtheacto gcnoinzsinegrv athtiaotn cofn stheerv agtliobna lo fe nthveir ognlmobeanlt eisn vironment• iTs he speci•fi cTahteio snpse acnifdic datimioenns saionnds d oimf pernosdiouncsts o ifn p trhoisd uccatsa liong t hairse csautbajleocgt atore c shuabnjegcet wtoit hcohuatn pgrei owr ithout prior

the top-prioritthye c thoapll-epnrgioer itfyo rc thhaell ewnogreld f’os r ptohpeu wlaotiroldn’,s Npipopounla tion, Nippon otice. notice.

Thompson wTillh coomnpdsuocnt iwtsi lla cotinvidtiuecst witsit ha ctoivnistiiedse rwatitiohn c onf sthidee ration of •th We hen the•s eW phreond uthcetss ea rper oexdpuocrtste adr,e t heex peoxrpteodrt,e trh seh eoxupldo rctoern fsirhmou ald f ocrownafrirdmin ga fcooruwnatrdyi nagn dc oau unstery, and, a use, and,

environment eansv iaro ncmorepnotr aatse as ocoiarlp oreraspteo nssoibcialitl y,r ersepdouncseib itlist y, reduce its

negative impnaecgt aotniv et hiem peancvtir oonnm tehnet , eannvdir ohnemlpe nfto, satenrd ah erilcph foster a ricihn case of fianl lcinags eu n odfe fra tllhineg c unsdtoemr tehre's cruesqtuoimreemre'sn rtes,q tuairkeem neenctess, stakrye pnreocceesdsuarreys p sruoche dausr esx psourcth as export

global environgmloebnatl. environment. permission paeprpmliicsastiionn .application.

• Although •a lAl dltahtoau ignh t hailsl dcatta liong t hiass c baetaelno gc ahraesf ublleye cno cmapreilfeudll yt oc ommapkeile tdh et oin mfoarkmea thioen i nafso crmomatpiolent ea sa sc omplete as

ISO 900IS1 O& 9104010 1& Q1u40a0li1ty Q suyastlietym s ystemp ossible, NpIPoPsOsiNbl eT,H NOIPMPPOSNO NTH COOM.,P LSTODN. s ChaOll. ,n LoTtD b.e s lhi ablll en ofot rb aen lyia dbalem foarg easn yw dhamtsaogeevse rw, dhiaretscot eovre r, direct or

indirect, basineddir uecpto, nb asneyd in ufopromna atnioyn i ninfo trhmisa ctiaotna liong t.h NisI PcPatOaNlo gT.H NOIPMPPOSNO NTH COOM.,P LSTODN. m CaOk.e, sL TnDo . makes no

registraretigoins tcrearttioifinc caetertificate warranty, eiwthaerr aenxtpyr, eesitsh oer iemxpirlesds, ionrc ilmudpiinlegd t,h ien cimlupdilnegd twhea rirmanptiyle dof w maerracnhtayn otaf bmilietyrc ohra fnitnaebsilsit yfo orr a f itness for a

particular ppuarprtoicsuel.ar purpose.

• Reproduc•ti oRne parnodd ucoctniovenr asinodn cwointhvoeurst iponer wmiitshsoiount paererm pirsoshioibni taerde. prohibited.

CAT-160C0AET-16P0rin0teEd in CPhrininat e©d 2in0 2C4h.i0n7a (©A2K0A2) 4.07 (AKA)

LINEAR MOTION ROLLING GUIDE BLUE

LINEAR MOTION ROLLING GUIDE BLUE

Page2

LINEAR MOTION ROLLING GUIDE

Good Environment and

Good Quality

IKO Linear Motion Rolling Guides are used with satisfactory results for various applications requiring precision

positioning such as semi-conductor manufacturing equipment, large sized machine tools, industrial robots,

and precision equipment.

In contrast to conventional rolling bearings used in rotating parts, Linear Motion Rolling Guides are the

products applicable to plane sliding surfaces, and meet the increasing needs for linear motion and precision

positioning in machines and equipment.

Linear Way and Linear Roller Way of Rail Guide Type, Linear Ball Spline of Shaft Guide Type, and other

products, recognized for their high quality and excellent features, are available.

Ⅰ̶1 Ⅰ̶2

Page3

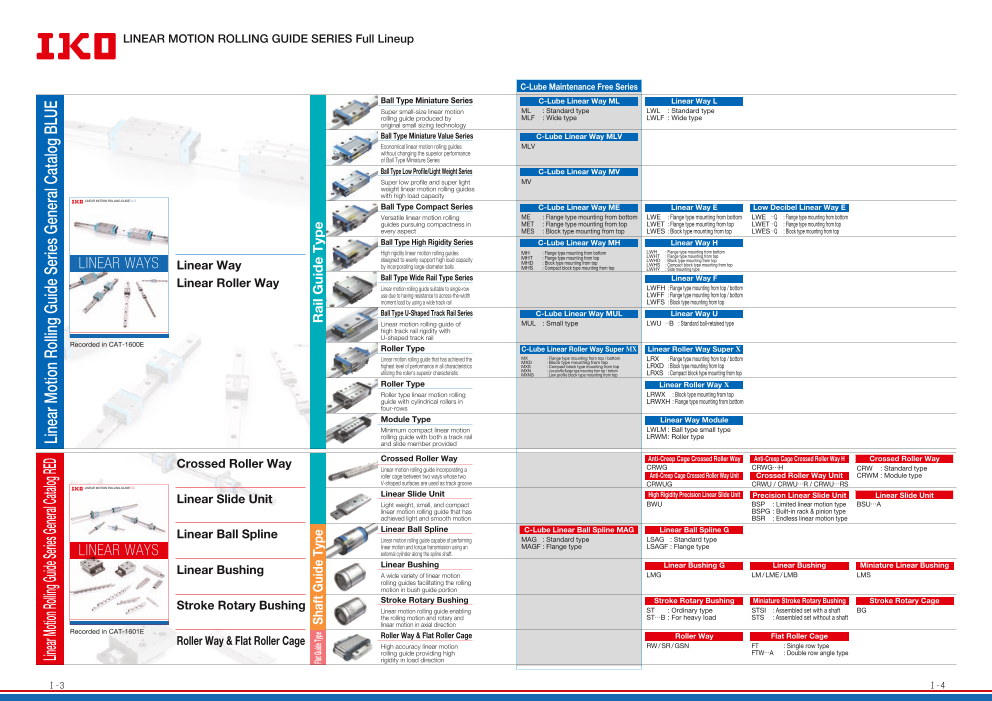

IKO Linear Motion Rolling Guide Series Full Lineup

LINEAR MOTION ROLLING GUIDE SERIES Full Lineup

C-Lube Maintenance Free Series

Ball Type Miniature Series C-Lube Linear Way ML Linear Way L

Super small-size linear motion ML : Standard type LWL : Standard type

rolling guide produced by MLF : Wide type LWLF : Wide type

original small sizing technology

Ball Type Miniature Value Series C-Lube Linear Way MLV

Economical linear motion rolling guides MLV

without changing the superior performance

of Ball Type Miniature Series

Ball Type Low Profile/Light Weight Series C-Lube Linear Way MV

Super low profile and super light MV

weight linear motion rolling guides

with high load capacity

LINEAR MOTION ROLLING GUIDE BLUE

Ball Type Compact Series C-Lube Linear Way ME Linear Way E Low Decibel Linear Way E

Versatile linear motion rolling ME : Flange type mounting from bottom LWE : Flange type mounting from bottom LWE …Q : Flange type mounting from bottom

guides pursuing compactness in MET : Flange type mounting from top LWET : Flange type mounting from top LWET …Q : Flange type mounting from top

every aspect MES : Block type mounting from top LWES : Block type mounting from top LWES …Q : Block type mounting from top

Ball Type High Rigidity Series C-Lube Linear Way MH Linear Way H

High rigidity linear motion rolling guides MH : Flange type mounting from bottom LWH : Flange type mounting from bottom

designed to evenly support high load capacity MHT : Flange type mounting from top LWHT : Flange type mounting from top

LINEAR WAYS Linear Way MHD : Block type mounting from top LWHD : Block type mounting from top

by incorporating large-diameter balls LWHS : Compact block type mounting from top

MHS : Compact block type mounting from top LWHY : Side mounting type

Linear Roller Way Ball Type Wide Rail Type Series Linear Way F

Linear motion rolling guide suitable to single-row LWFH : Flange type mounting from top / bottom

use due to having resistance to across-the-width LWFF : Flange type mounting from top / bottom

moment load by using a wide track rail LWFS : Block type mounting from top

• The specifications and dimensions of products in this catalog are subject to change without prior

• When these products are exported, the exporter should confirm a forwarding country and a use, and,

in case of falling under the customer's requirements, take necessary procedures such as export Ball Type U-Shaped Track Rail Series C-Lube Linear Way MUL Linear Way U

• Although all data in this catalog has been carefully compiled to make the information as complete as

possible, NIPPON THOMPSON CO., LTD. shall not be liable for any damages whatsoever, direct or

indirect, based upon any information in this catalog. NIPPON THOMPSON CO., LTD. makes no

warranty, either express or impiled, including the impiled warranty of merchantability or fitness for a Linear motion rolling guide of MUL : Small type LWU …B : Standard ball-retained type

• Reproduction and conversion without permission are prohibited.

CAT-1587E Printed in China © 2021.08 (AKA) high track rail rigidity with

U-shaped track rail

Recorded in CAT-1600E Roller Type C-Lube Linear Roller Way Super MX Linear Roller Way Super X

Linear motion rolling guide that has achieved the MX : Flange type mounting from top / bottom LRX : Flange type mounting from top / bottom

MXD : Block type mounting from top

highest level of performance in all characteristics MXS : Compact block type mounting from top LRXD : Block type mounting from top

utilizing the roller's superior characteristic MXN : Low profile flange type mounting from top / bottom

MXNS : Low profile block type mounting from top LRXS : Compact block type mounting from top

Roller Type Linear Roller Way X

Roller type linear motion rolling LRWX : Block type mounting from top

guide with cylindrical rollers in LRWXH : Flange type mounting from bottom

four-rows

Module Type Linear Way Module

Minimum compact linear motion LWLM : Ball type small type

rolling guide with both a track rail LRWM : Roller type

and slide member provided

Crossed Roller Way Crossed Roller Way Anti-Creep Cage Crossed Roller Way Anti-Creep Cage Crossed Roller Way H Crossed Roller Way

Linear motion rolling guide incorporating a CRWG CRWG···H CRW : Standard type

roller cage between two ways whose two Anti-Creep Cage Crossed Roller Way Unit Crossed Roller Way Unit CRWM : Module type

V-shaped surfaces are used as track groove CRWUG CRWU / CRWU…R / CRWU…RS

LINEAR MOTION ROLLING GUIDE RED

Linear Slide Unit Linear Slide Unit High Rigidity Precision Linear Slide Unit Precision Linear Slide Unit Linear Slide Unit

Light weight, small, and compact BWU BSP : Limited linear motion type BSU…A

linear motion rolling guide that has BSPG : Built-in rack & pinion type

achieved light and smooth motion BSR : Endless linear motion type

Linear Ball Spline Linear Ball Spline C-Lube Linear Ball Spline MAG Linear Ball Spline G

Linear motion rolling guide capable of performing MAG : Standard type LSAG : Standard type

LINEAR WAYS linear motion and torque transmission using an MAGF : Flange type LSAGF : Flange type

external cylinder along the spline shaft.

Linear Bushing Linear Bushing Linear Bushing G Linear Bushing Miniature Linear Bushing

A wide variety of linear motion LMG LM / LME / LMB LMS

rolling guides facilitating the rolling

motion in bush guide portion

• The specifications and dimensions of products in this catalog are subject to change without prior

• When these products are exported, the exporter should confirm a forwarding country and a use, and,

in case of falling under the customer's requirements, take necessary procedures such as export

• Although all data in this catalog has been carefully compiled to make the information as complete as

possible, NIPPON THOMPSON CO., LTD. shall not be liable for any damages whatsoever, direct or

indirect, based upon any information in this catalog. NIPPON THOMPSON CO., LTD. makes no

warranty, either express or impiled, including the impiled warranty of merchantability or fitness for a Stroke Rotary Bushing Stroke Rotary Bushing Stroke Rotary Bushing Miniature Stroke Rotary Bushing Stroke Rotary Cage

• Reproduction and conversion without permission are prohibited. Linear motion rolling guide enabling ST : Ordinary type STSI : Assembled set with a shaft BG

CAT-1588E Printed in China © 2021.09 (AKA) the rolling motion and rotary and ST…B : For heavy load STS : Assembled set without a shaft

linear motion in axial direction

Recorded in CAT-1601E

Roller Way & Flat Roller Cage Roller Way & Flat Roller Cage Roller Way Flat Roller Cage

High accuracy linear motion RW / SR / GSN FT : Single row type

rolling guide providing high FTW…A : Double row angle type

rigidity in load direction

Ⅰ̶3 Ⅰ̶4

Linear Motion Rolling Guide Series General Catalog RED Linear Motion Rolling Guide Series General Catalog BLUE

Flat Guide Type Shaft Guide Type Rail Guide Type

LINEAR MOTION ROLLING GUIDE BLUE LINEAR MOTION ROLLING GUIDE RED

Page4

IKO Linear Motion Rolling Guide Series Classification and features

LINEAR MOTION ROLLING GUIDE SERIES Classification and

features

Types of Linear Motion Rolling Guides Specifications of Linear Motion Rolling Guides

Endless linear motion Limited linear motion Linear Way

● NC machine tool

● Precision working

Linear Way Crossed Roller Way machine BLUE

● Robot

Endless ● Transfer machine

Ball linear motion Complex load, medium to heavy load

The Rail Guide Type achieves linear

motion along a rail. This product can Linear Roller Way ● Heavy duty

receive a complex load and features machine tool

●

high performance, excellent total Large working

machine BLUE

balance and easy handling. Endless ● High-rigidity

Roller linear motion Complex load, heavy to extra-heavy load robot

Linear Roller Way Linear Slide Unit Crossed Roller Way ● Precision working

machine

● Electronic parts

assembling machine RED

Limited ● Precision measuring

Roller linear motion Complex load, medium load instrument

Linear Slide Unit

● Electronic parts

assembling

machine RED

Limited

Endless linear motion Limited linear motion + rotation Ball linear motion Complex load, light to medium load

Linear Ball Spline Stroke Rotary Bushing Linear Ball Spline ● Robot

● Testing and

inspection

equipment RED

The Shaft Guide Type achieves linear

motion along a shaft. This product is Endless ● Transfer

easy to handle and suitable for relatively Ball linear motion Complex load, medium to heavy load machine

low load conditions. Some shaft guide Linear Bushing ● Packaging

products can achieve both rotation and machine

reciprocating linear motion. ● Measuring

instrument RED

Linear Bushing Endless ● Medical

Ball linear motion Radial load, light load instrument

Stroke Rotary Bushing

● Printing press

● Press die set

● Precision RED

measuring

Limited linear instrument

Ball motion + rotation Radial load, light load

Roller Way

● NC machine

tool

The Flat Guide Type achieves linear Endless linear motion Limited linear motion ● Precision RED

motion on a surface. This product can working

receive only a unidirectional load but Roller Way Flat Roller Cage Endless machine

Roller linear motion Unidirectional load, extra-heavy load

feature high rigidity in the load direction.

Flat Roller Cage ● Precision

working

machine

● Optical RED

Limited measuring

Roller linear motion Unidirectional load, extra-heavy load instrument

Code description Excellent Good Fair

Ⅰ̶5 Ⅰ̶6

Flat Guide Type Shaft Guide Type Rail Guide Type

Guide Type

Flat Guide Type Shaft Guide Type Rail Guide Type

Limited Endless Limited

linear motion linear motion linear motion Endless linear motion Limited linear motion Endless linear motion+ rotation

Type of rolling

element

Type of

motion

Load

direction and

load carrying

capacity

Rigidity

Frictional

characteristic

Ease of

mounting

General

applications

Item-listed

catalog

Page5

Linear Motion Rolling Guides Series General Catalog BLUE INDEX

LINEAR MOTION ROLLING GUIDE SERIES BLUE INDEX

Ball Type Miniature Series Ball Type Wide Type Series

C-Lube Linear Way ML Linear Way F

Linear Way L / Micro Linear Way L LWFS LWFF LWFH

ML LWL Linear motion rolling guide suitable to single-row use

Super small-size linear motion rolling guide due to having resistance to across-the-width

produced by original small sizing technology moment load by using a wide track rail

Ⅱ-5 Ⅱ-135

Ball Type Miniature Value Series Ball Type U-Shaped Track Rail Series

C-Lube Linear Way MLV C-Lube Linear Way MUL

MLV Linear Way U

Economical linear motion rolling guides without MUL LWU

changing the superior performance of Ball Type Linear motion rolling guide of high track rail rigidity

Miniature Series with U-shaped track rail

Ⅱ-41 Ⅱ-157

Ball Type Low Profile/Light Weight Series Roller Type

C-Lube Linear Way MV C-Lube Linear Roller Way Super MX

MV Linear Roller Way Super X

Super low profile and super light weight linear MX LRX

motion rolling guides with high load capacity Linear motion rolling guide that has achieved the

highest level of performance in all characteristics

utilizing the roller's superior characteristic

Ⅱ-51 Ⅱ-171

Ball Type Compact Series Roller Type

C-Lube Linear Way ME Linear Roller Way X

Linear Way E / Low Decibel Linear Way E LRWX

ME LWE Roller type linear motion rolling guide with cylindrical

Versatile linear motion rolling guides pursuing rollers in four-rows

compactness in every aspect

Ⅱ-63 Ⅱ-219

Ball Type High Rigidity Series Module Type

C-Lube Linear Way MH Linear Way Module

Linear Way H LWLM LRWM

MH LWH Minimum compact linear motion rolling guide with

High rigidity linear motion rolling guides designed to both a track rail and slide member provided

evenly support high load capacity by incorporating

large-diameter balls

Ⅱ-89 Ⅱ-233

Ⅰ̶7 Ⅰ̶8

Page6

2011.07.27 再校 CAT-1552-1 Ⅰ04-24

Gentle to The Earth

Nippon Thompson Co., Ltd. is working to develop global

environment-friendly products.

It is committed to developing products that make its

customer's machinery and equipment more reliable, Gentle to The Earth

thereby contributing to preserving the global environment.

This development stance manifests well in the keyword

"Oil Minimum".

Our pursuit of Oil Minimum has led to the creation of ’s

proprietary family of lubricating parts as "C-Lube".

"C-Lube" minimizes usage of lubrication oil and supplies the

optimal amount of lubrication oil for long period of time. So it

realizes long term maintenance free and contributes to the

global environment preservation.

The "Interchangeable" is a result of our consideration

to the environment and radical pursuit of

elimination of material and inventory waste.

Interchangeable is a collective name of "systems of products selection

from users' perspective" which allows free interchange and replacement

totally retaining the accuracy and preload of slide units and track rails.

The integration of maintenance free and

advanced interchangeable system with

C-Lube is the "Free & Interchangeable".

Ⅰ-9 Ⅰ-10

Page7

Features of Maintenance Free Series

2011.07.27 再校 CAT-1552-1 Ⅰ04-24

Features of Maintenance Free Series ①

Eco-friendly specification Reducing usage of lubrication oil

Gentle to The Earth

U.S. PATENTED

C-Lube Linear Way ML Linear Way L

No. 7677804 No. 7258486

7252435 6517244

6729761 6176617

6712511 6082899 Eco-friendly Maintenance free Compactness

5967667

C-Lube Linear Way MLV

No. 8465206 Linear Way E

No. 7677804 Consumption of precious oil resource is Endures running over 20,000 km The space consuming oil feeder is

C-Lube Linear Way MV 6176617

5967667 minimized! And elimination of oil feeder without oil feeding! eliminated to save the space!

No. 6712511

6729761 Linear Way H and its piping reduces the initial cost!

C-Lube Linear Way ME No. 7677804 6082899

6517244 5967667 Troublesome lubrication maintenance Freedom of machine designing

No. 7748905 6461045 5622433

7677804 6250805

6729761 6176617 Contributes to reduction of total cost

6712511 process is reduced!! is expanded for user!!

Linear Way F

C-Lube Linear Way MH and environmental loads!!

No. 6176617

No. 7832929 6712511 5967667

7762723

7748905 Distance equivalent to

7677804 Linear Way U Efficient use of space

6729761 No. 6880975 6176617 Oil usage reduction effect halfway around the

6851857 6082899

C-Lube Linear Way MUL 6517244 5967667 globe

6461045

No. 5435649 6309107

C-Lube Linear Roller Way Super MX

No. 8403563 7950852 No. 8585288 7458721

8403562 7927016 8506166 7458720

8123408 7862234 8206036 5800064

8113714 7832930 8113714

8033730 7780356

7997800 7534042

Linear Roller Way Super X

No. 7832930 6766897 No. 7341378 5622433 Oil

7458721 6461045 5967667 5464288

7458720 6176617 5800064

Ⅰ-11 Ⅰ-12

Page8

2011.07.27 再校 CAT-1552-1 Ⅰ04-24

Features of Maintenance Free Series ②

Featturres off C--Lube Liinearr Way and C--Lube Liinearr Rollllerr Way Long term maiintenance free iis realliized wiith oiill

Gentle to The Earth

Oriigiinall and worlld''s first iimpregnated wiith C-Lube onlly

structure with [C-Lube] !!

Maintenance free Durability test result

Linear Way No C-Lube

C-Lube Linear Way C-Lube Linear Roller Way (No grease) 4.9 km lubrication shortage damage

LWL9

This endures running over 20,000 km without

C-Lube Linear Way C-Lube integrated Running of 86,000 km without failure

oil feeding with lubrication oil in the C-Lube ML9 High-speed at 240 m/min

No grease

The aquamarine end plate is the only. C-Lube integrated

High acceleration / deceleration 26G Running of 46,000 km without failure

symbol of maintenance free. Furthermore, grease is pre-packed in the slide No grease

C-Lube integrated

unit so long term maintenance free can be Load of 0.09C Running of 89,000 km without failure

No grease

realized. C-Lube Linear Way C-Lube integrated Running of 71,000 km without failure

ME25 Load of 0.1C

No grease

Maintenance free is achieved C-Lube Linear Roller Way C-Lube integrated Running of 56,000 km without failure

MXG45 Load of 0.1C

*1 No grease

until the end of device life !

0 20 000km 40 000 60 000 80 000 100 000

*1. Typical device life is assumed. Re-greasing may

be necessary depending on use conditions. Traveling distance km

Eco-friendly Oil supply test result 100 No pre-packed grease

No applied load

80 ML9

As lubrication oil in C-Lube is supplied by the ML12

ML15

amount necessary to maintain lubrication perfor- 60

mance of the rolling guide, the consumption of

40

lubrication oil is reduced and lubrication perfor-

mance is maintained even when it run for a long 20

period.

0

Eco-friendly specification reducing 0 20 000km 40 000 60 000 80 000 100 000

Traveling distance km

usage of lubrication oil!

C-Lube integrated Compact External lubrication parts

Lubrication oil is carried through Lubrication oil is directly supplied As C-Lube Linear Way and C-Lube Linear Roller Linear Way using

conventional lubrication parts

circulation of rolling elements to surfaces of the rolling elements Way are integrated with lubrication part C-Lube,

C-Lube Linear Way

their slide units are not long unlike types with

The lubrication oil is supplied directly to the rolling elements, The surface of capillary lubricating element is always covered external lubrication parts.

not to the track rail. with the lubrication oil.

Replacement of conventional parts is easy free

When rolling elements make contact with the capillary lubri- Lubrication oil is continuously supplied to the surface of

cating element integrated with the circulation path of slide rolling elements by surface tension in the contact of capillary from constraints of mounting space and stroke

unit rolling elements, the lubrication oil is supplied to lubricating element surface and rolling elements. length.

surfaces of rolling elements and carried to the loading area On the surface of capillary lubricating element with which the

through circulation of rolling elements. rolling elements make contact, new lubrication oil is always Compact design taking into

This results in adequate lubrication oil being properly main- supplied from the other sections.

tained in the loading area and lubrication performance will account compactness!

last for a long time.

Cylindrical rollers Cylindrical rollers

Smooth Frictional resistance 3.0 ML9 standard preload

C-Lube test result

Cylindrical rollers Lubrication

oil film

Surface C-Lube Linear Way and C-Lube Linear Roller

tension 2.0

Way do not generate slide resistance unlike lubri-

cation parts external to the slide unit that make

contact with the track rail. 1.0

Capillary

C-Lube C-Lube Driving force follow-up property is superior and

Track rail

Slide unit stroke direction

energy is saved by improvement of accuracy and

0

reduction of friction loss. 0 50 100 150

Light and smooth motion is achieved! Traveling distance mm

Ⅰ-13 Ⅰ-14

Frictional resistance N Lubrication oil supply amount

wt%

Page9

Features of Interchangeable Specification

2011.07.27 再校 CAT-1552-1 Ⅰ04-24

Features of Interchangeable Specification ①

Ultimate Interchangeable system by radical

pursuit of elimination of any waste

Accuracy interchangeability Unit interchangeability Short delivery products

Three accuracy classes are available! Many type of slide units are available! Separate delivery of slide unit and track rail!

Height variation can be controlled Every slide unit is interchangeable

with multiple assembled sets! with the same track rail! You may order what you need by

High accuracy of the device can be any quantity at any time!!

maintained in the multiple-use environment!! It is easily added

or replaced!!

Q I dropped the Linear Way unit by

mistake, and the unit is damaged.

Sounds great!

Can I replace it? AUnit interchangeability Q Calculated accuracy cannot be

Fine accuracy

achieved after assembly of the

device?

Dropped

If you use Linear Way of AAccuracy interchange-

ability, preload inter-

Accuracy not changeability

improved

How do you like to use accuracy

Interchangeable specifica- higher by one class or higher

tion, you may need to preload type?

replace only slide unit. As accuracy of the interchange-

Oh, dear! It's

going to be late able products is controlled strictly

Please modify by parts, setting can be modified.

my accuracy

Q I need to increase the rigidity of the Power up

unit because of sudden specifica-

tion change. AUnit interchangeability Q I carelessly forgot to arrange some

Sounds great!

parts, but I need them urgently.

Can it be delivered soon?

I want to be AShort delivery available

long type...

If late... Interchangeable parts are

The rigidity can be improved available for short delivery,

easily by increasing the unit they can be delivered

length. quickly with our perfect

inventory system.

Slide unit and track rail can

Need more I forgot to

arrange be ordered individually.

rigidity

Ⅰ-15 Ⅰ-16

Page10

2011.07.27 再校 CAT-1552-1 Ⅰ04-24

Features of Interchangeable Specification ②

Free combination is enabled for model, accuracy, preload!! Interchangeable specification has realized the incomparable high interchangeability by severely managing

Ultimate interchangeable system the dimensions of slide unit and track rail with the background of unique high processing technology.

This feature allows independent handling of slide unit and track rail, thus allowing you to select free combina-

Interchangeable specification tion and to order any products for any volume at any necessary time.

Interchangeable specification realizes ; Accuracy interchangeability

Requirements of ;

●

● Wish to improve the rigidity and life of machines Wish to prepare for a sudden design change Three accuracy classes of Ordinary, High and Standard setting up to precision C

●

● Wish to improve the accuracy of machines Wish to select freely the combination of high Precision class are provided, to support even ● Tolerances of dimensions H and N

accuracy and preload high traveling accuracy purposes. In addition,

● Wish to replace the slide unit immediately ● Variation of dimensions H and N in 1 set

● Slide unit and track rail are separately handl as height variation of multiple assembled sets is ● Parallelism in operation of the C surface to A surface

● TheH number of selide unilts is pin short

● Free combination managed with high accuracy, you may use ● Parallelism in operation of the D surface to B surface

● Wish to replace the track rail immediately parallel track rails at ease.

● The length of track rail is not sufficient eof slidde uni t anod trauted

ck rail

can be selected

N

● Compactness-ind pendent storing of slide A

● Wish to store only the slide units in stock D B

units and track rails

for emergency Sort

It allows the accuracy improvement of

units without design changes!

Select the products as many as you wish.

Slide unit Track rail Set condition Corresponding to parallel arrangement

of multiple assembled sets as standard

● Variation of dimensions H of multiple

assembled sets is specified

Preload interchangeability

The high accuracy dimensions management utilizing the simple

structure achieved the interchangeability of preloaded slide units. Light preload er

It supports the applications requiring the rigidity of one higher rank. Takeo

v

Standard preload

Unit interchangeability High preload setting is possible thanks

to high accuracy dimensions control

A wide variety of slide unit models with different sectional Interchangeability of track rail

shape and length are provided, for free replacement on the Track rail

same track rail.

High carbon Stainless steel-made Butt-jointing

steel-made track rail track rail track rails

Slide unit Rigidity is

necessary after all!

Interchangeability of slide unit

Slide unit shape It allows the rigidity improvement of

Flange type mounting from bottom Flange type mounting from top Block type mounting from top Compact block type

mounting from top units without design changes!

Track rail

Maintenance free is achieved only by replacing the slide unit!

Length of slide unit By replacing the interchangeable Linear Way or Linear

Short unit Standard unit Long unit Roller Way slide unit with C-Lube Linear Way or C-Lube

Linear Roller Way slide unit, maintenance free is achieved

while using the same track rail.

Free selection is possible for

slide units and track rails!

Ⅰ-17 Ⅰ-18

H

Page11

Features of Linear Way Series

2011.07.27 再校 CAT-1552-1 Ⅰ04-24

Features of Linear Way Series

's excellent features realized by a simple structure by four-points

contact in two-row raceways

Two-row four-point contact type simple structure Interchangeable

IKO adopts two-row four-point contact type for every The simple structure of four-contact in two-row raceway yields small

Linear Way series. Thanks to our design know how and manufacturing errors or accuracy measurement errors, allowing the

production technologies having been fostered for long maintenance of each raceway in the high dimensions accuracy.

time, high accuracy and smooth motion are realized in

the micro series. This technology realizes interchangeable

In addition, load in every Track rail Slide unit

direction can be received specification and high interchangeable

system in every series! Measurement of way accuracy

evenly and therefore stable

high accuracy and rigidity As the ball is stabilized during track groove measure-

can be achieved even in ment, measurement of high accuracy and precise pre-

applications where load has load management are possible.

variable direction and size or Four-point Simple two-row four-point

complex load is applied. contact structure contact structure

Variety of models and size variations

Essential for micro sizing! A wide variety of models and sizes, such as super miniature size of only 1 mm

track rail width, is provided for your selection to meet each requirement.

Series Model Size Track rail width

Micro Linear Way L realized by simple structure Min Max

C-Lube Linear Way ML ML 20 models 15 sizes 3 ~ 42 mm

Micro Linear Way L for further needs of miniaturization

Linear Way L LWL 22 models 19 sizes 1 ~ 42 mm

produced by original small sizing technology.

Wide variety of track rail width from 1 mm to 6 mm is C-Lube Linear Way MLV MLV 1 model 3 sizes 7 ~ 12 mm

available and high accuracy of micro positioning mecha-

nism is realized. C-Lube Linear Way MV MV 1 model 3 sizes 20 ~ 30 mm

C-Lube Linear Way ME ME 18 models 6 sizes 15 ~ 45 mm

Linear Way E LWE 21 models 6 sizes 15 ~ 45 mm

C-Lube Linear Way MH MH 17 models 9 sizes 8 ~ 45 mm

Linear Way H LWH 19 models 11 sizes 8 ~ 65 mm

Track rail width

Linear Way F LWF 4 models 7 sizes 33 ~ 90 mm

C-Lube Linear Way MUL MUL 1 model 2 sizes 25 ~ 30 mm

Linear Way U LWU 1 model 4 sizes 40 ~ 86 mm

World's smallest size!

● High accuracy even with the smallest size of 1 mm*!

*Track rail width of 1 mm

● Even the smallest size of 1 mm can be securely mounted and fixed**!

**Tapped rail specification

Micro Linear Way L ● Even the smallest size of 1 mm can ensure stable operation!

LWL1 LWL1 can be used for further super miniaturization

of machines and devices with free-minded thinking.

1N=0.102kgf=0.2248lbs.

Ⅰ-19 1mm=0.03937inch Ⅰ-20

Page12

Features of Linear Roller Way Series

2011.07.27 再校 CAT-1552-1 Ⅰ04-24

Features of Linear Roller Way Series ①

Ultimate high performance produced by world's first roller guide structure of

Super high load capacity Super high rigidity

The Linear Roller Way Super X has a large contact area with The rigidity of linear motion rolling guide significantly

the way and a number of cylindrical rollers with excellent load affects properties of machines and devices to be incorpo-

capacity, which allows to achieve larger load rating. rated.

The Linear Roller Way Super X achieves high rigidity as a

Comparison of basic dynamic load rating Comparison of basic static load rating number of small cylindrical rollers with smaller elastic Comparison of elastic deformation

deformation relative to load than that of balls are incorpo-

600 000 900 000 rated in the slide unit. 30

Roller type( MX and LRX) Roller type( MX and LRX)

Ball type( MH and LWH) 800 000 Ball type( MH and LWH) MX25( Roller type)

500 000 Inertia 25

700 000 F=ma

MH25( Ball type)

400 000 600 000 20

500 000

300 000 15

400 000

200 000 300 000 10

200 000

100 000 5

100 000

0 0 0

10 12 15 20 25 30 35 45 55 65 85 100 10 12 15 20 25 30 35 45 55 65 85 100 0 5 000 10 000 15 000 20 000

Size Size Load N

Size smaller by one size than

Well-balanced high rigidity is

the ball type can be used! realized in every direction!

Long life

《Roller Type》 MXG45 《Ball Type》 MHG45

Same size

C:Basic dynamic load rating N

C = 124 000 N C = 95 200 N C0:Basic static load rating N

L:Life km

C0 = 223 000 N C0 = 114 000 N P:Applied load N

Roller type has large basic dynamic load rating C and long life due to the different "index"!

【Life calculation example】

Roller Type Ball Type

10/3 3

L=50(—C—) L=50(—C—P P )

Applied load Significant

In case of 10000 N increase!

L≒220 000 km L≒43 000 km

1N=0.102kgf=0.2248lbs.

Ⅰ-21 1mm=0.03937inch Ⅰ-22

Basic dynamic load rating N

Basic static load rating N

Displacement μm

Page13

2011.07.27 再校 CAT-1552-1 Ⅰ04-24

Features of Linear Roller Way Series ②

Vibration characteristics Corresponding to compactification

The Linear Roller Way Super X has high rigidity relative to Roller type with significantly higher load capacity than the ball

Vibration damping curve in downward vibration (Half amplitude)

ball types of the same size, so deformation amount is low type. The Linear Roller Way Super X allows for downsizing

relative to repeated fluctuating load, natural frequency is high 250 from many size variations for compactification of devices.

and vibration damping time is short.

200

Impulse hammer

MX15( Roller type)

Acceleration pickup To make the device needs to be more compact To make the device needs to be compact To increase the load capacity To make the device needs to be more compact

150 while maintaining the load capacity… while maintaining the load capacity… For example, when with the same size… while maintaining the load capacity…

Jig X・e-2・π・f0・ζ・t X:Initial amplitude MH15( Ball type) LWH55…B

f0:Natural frequency 〈Ball Type〉 is used

ζ:Damping ratio 100 MXN45 MX45 MX55 MXN55

t:Time 〈Roller Type〉 〈Roller Type〉 〈Roller Type〉 〈Roller Type〉

t

Bed 50

Vibration damping curve

0

0 0.01 0.02 0.03 0.04 0.05

Positioning time can be shortened! Time s Downsizing

Same size Same size

Same size

Allows accurate positioning with excellent frictional characteristic

The Linear Roller Way Super X prevents skew of cylindrical

MXDL25 and MXDG45 T3 preload frictional resistance

roller and achieves smooth motion by adopting unique retain- C = 95 400 N Same load C = 95 400 N C = 113 000 N Load capacity C = 148 000 N Same load C = 148 000 N

Test portion Extra long unit MXDL25 C0 = 159 000 N capacity C0 = 159 000 N C0 = 121 000 N increased C0 = 248 000 N capacity C0 = 248 000 N

ing method to accurately guide cylindrical roller ends with

retaining plate. Long unit MXDG45

The Linear Roller Way Super X has good response character- Preload T3 preload

Velocity 0.6 m/min

istics to micro-feeding and allows for accurate positioning,

Lubrication C-Lube integrated, with grease

thanks to small frictional resistance against preload and load

Downsizing Downsizing Same size Downsizing

and excellent frictional characteristics relative to plain guides 50

and ball type linear motion rolling guide. MXDL25

40 MXDG45

30 Downsizing and Roller type with large

High follow-up property is 20 increased load capacity! increase of load capacity!

ensured even for micro-feeding! 10

0

0 100 200 300 Compatible ball type and mounting dimensions

Distance mm

The Linear Roller Way Super X has mounting dimensions

High running accuracy compatible with the ball type Linear Way H. 《Roller Type》 《Ball Type》

Replacement with roller type is possible without significant C-Lube C-Lube

design change to machine or device. Linear Roller Way Super MX Linear Way MH

Optimal design based on analysis of re-circulation behavior of 246

cylindrical roller circulation realizes smooth and quiet motion. 500 Flange type

In addition, load is applied to many cylindrical rollers and

therefore the micro deflection during running is minimized.

Extra long unit is optimal for applications requiring higher MX MH, MHT

308

running accuracy. (For more information, see page Ⅰ-29)

Block type

Deflection amount during running

unit: μ m

MXDG30 T3 preload 0.12 Stable running accuracy is MXD MHD

achieved! Downsizing and increased Compact block type

load capacity are possible!

MXS MHS

1N=0.102kgf=0.2248lbs.

Ⅰ-23 1mm=0.03937inch Ⅰ-24

X

(Half amplitude)

Frictional resistance N Compliance x 10-9 m/N

Page14

Models and Size Variations

2011.07.09 初校 CAT-1552-1 Ⅰ25-50

Models and Size Variations ①

A variety of models and size variations

Ball Type Miniature Series Ball Type Compact Series

C-Lube Linear Way ML C-Lube Linear Way ME

C-Lube Linear Way MLV Linear Way E

Linear Way L Low Decibel Linear Way E

Versatile linear motion rolling guide that has achieved utility pursuing com-

Thanks to the structure with two rows of balls to contact with the way at

pactness in every aspect. Low decibel types with resin separator to prevent

four points, stable accuracy and rigidity can be achieved even in applica-

direct contact between balls are also available.

tions where load has variable direction and size or complex load is applied,

despite its very small body.

Flange type Flange type Block type

mounting from bottom mounting from top mounting from top Length of slide unit Size

Micro Linear Way L Short 15, 20, 25, 30, 35, 45

C

ME MET MES

LWE LWET LWES Standard

As the lineup of track rail width from 1 mm to 6 mm is available, you can select an optimal No

symbol

product for the specifications of your machine and device. For LWL1, world's smallest

size is realized: track rail width of 1 mm, slide unit width of 4 mm and assembly height of Long

2.5 mm. G

Standard type Wide type Length of slide unit Size

ML MLF Short Standard 1, 2, 3, 5, 7, 9, 12, 15, 20, 25

LWL LWLF C type

Wide type 2, 4, 6, 10, 14, 18, 24, 30, 42 Ball Type High Rigidity Series

Standard

No

symbol C-Lube Linear Way MH

Long

G Linear Way H

Extra long

L

High rigidity linear motion rolling guides designed to evenly support high

load capacity by incorporating large-diameter balls. Stable accuracy and

rigidity can be achieved even in applications where load with variable direc-

Ball Type Low Profile/Light Weight Series tion and size and complex load are applied.

C-Lube Linear Way MV

Flange type Flange type Block type Compact block type Length of slide unit

Despite its extra low profile and extra light weight, this linear motion rolling mounting from bottom mounting from top(1) mounting from top mounting from top Short

guide has the maximum load rating among the ball types while achieving MH MHT MHD MHS C

high load capacity. LWH LWHT LWHD LWHS

No Standard

symbol

Long

G

Length of slide unit Size

Standard 20, 25, 30

Note( 1) Some models may be mounted from bottom. Size

8, 10, 12, 15, 20, 25, 30, 35, 45, 55, 65

1N=0.102kgf=0.2248lbs.

Ⅰ-25 1mm=0.03937inch Ⅰ-26

Page15

2011.07.09 初校 CAT-1552-1 Ⅰ25-50

Models and Size Variations ②

A variety of models and size variations

Ball Type Wide Type Series Roller Type

Linear Way F C-Lube Linear Roller Way Super MX

Linear Roller Way Super X

As wide track rail is used and the distance between the load points is long,

this is a linear motion rolling guide suitable to single-row use due to the

structure resistant to across-the-width moment load. It is also resistant to Linear motion rolling guide that has achieved the highest level of perfor-

complex load. mance in all characteristics utilizing the roller's superior characteristic, such

as rigidity, load capacity, running accuracy and vibration damping property.

With extra long unit with the maximum slide unit length, load capacity and

rigidity are improved and running performance with super high accuracy is

realized.

Flange type Block type Compact block type Low profile flange type Low profile block type

Flange type Flange type Block type Length of slide unit mounting from top / bottom mounting from top mounting from top mounting from top mounting from top

mounting from top / bottom mounting from top / bottom mounting from top No Standard MX(1) MXD MXS MXN MXNS

LWFH LWFF LWFS symbol LRX(1) LRXD LRXS

Size

LWFH 40,60,90

LWFF 33,37,42,69

LWFS 33,37,42

Note( 1) Size 20 series allows only for mounting from top and model mounting from bottom is MXH and LRXH.

Length of slide unit Size

C No symbol G L 10, 12, 15, 20, 25, 30, 35, 45, 55, 65, 85, 100

Short Standard Long Extra long

Ball Type U-Shaped Track Rail Series

C-Lube Linear Way MUL

Linear Way U Four-row roller guide of world's smallest size

Track rail width of 10 mm

Linear motion rolling guide of the structure with way inside the track rail of

U-shaped section and slide unit therein. With the U-shaped track rail, rigidi-

ty against the track rail moment load and torsion is significantly improved.

Small type Standard type Length of slide unit

MUL LWU No Standard

symbol Super high rigidity

Size Super high load capacity

MUL 25, 30

High running performance Stainless steel made

LWU 40, 50, 60, 86

Excellent frictional characteristics LRXD10…SL

1N=0.102kgf=0.2248lbs.

Ⅰ-27 1mm=0.03937inch Ⅰ-28

Page16

2011.07.09 初校 CAT-1552-1 Ⅰ25-50

Models and Size Variations ③

Features of extra long unit

Length of slide unit is 1.4 to 1.5 times longer

C-Lube Linear Roller Way Super MX Further improvement of running accuracy

than that of standard unit

Load capacity and rigidity are significantly improved!!

Load capacity of machine or device is improved

Long unit As its basic dynamic load rating and basic static load rating are larger

MX(D,S)G

MXN(S)G 1.2 to 1.3 times than those of Long type by 122% and 129%, respectively, life and

margin safety of machine or device are improved.

Comparison of basic dynamic load rating Comparison of basic static load rating

Increased to 158% relative to standard unit! Increased to 181% relative to standard unit!

Increased to 122% relative to long unit! Increased to 129% relative to long unit!

(In case of MXL45) (In case of MXL45)

Standard unit 800 000 1400 000

MX(D,S) Short unit Short unit

700 000

Standard unit 1200 000

MXN(S) Standard unit

1.4 to 1.5 times

600 000 Long unit Long unit

1000 000

Extra long unit Extra long unit

500 000

800 000

400 000

600 000

300 000

400 000

200 000

100 000 200 000

Extra long unit 0 0

Size 20 Size 25 Size 30 Size 35 Size 45 Size 55 Size 65 Size 85 Size 20 Size 25 Size 30 Size 35 Size 45 Size 55 Size 65 Size 85

MX(D,S)L

MXN(S)L

Super accurate feeding mechanism is realized 420 mm

500 mm Contributing to improvement of machine or device rigidity

As running accuracy is as low as a half of that of long unit, feeding

600 mm Elastic deformation relative to load is small in comparison with Load Load

mechanism with super high accuracy can be realized. long unit, device rigidity is improved, accuracy is improved, and

Measuring position resonance can be avoided. Measuring method

423 mm

Test conditions 0.2

Test Extra long unit

0.1 Deflection amount 0.07 μm

portion MXDL45 Comparison of elastic deformation under downward load Comparison of elastic deformation under upward load

Preload T3 preload 0

Rigidity increased to 155% relative to standard unit! Rigidity increased to 152% relative to standard unit!

-0.1

-0.2 Rigidity increased to 117% relative to long unit! Rigidity increased to 113% relative to long unit!

600 mm 30 40 50 60 70 80 90 100

463 mm Traveling distance mm (With displacement of 10 μm for Size 45) (With displacement of 10 μm for Size 45)

Test conditions 45 45

0.2 MXD45 T3 preload( Standard unit) (stanMdaXrDd 4u5n it) T3 preload( Standard unit)

Test Long unit Deflection amount 0.12 μm 40 40

0.1 MXDG45 T3 preload( Long unit) (longM unXitD) G45 T3 preload( Long unit)

portion MXDG45 35 MXDL45 T3 preload( Extra long unit) 35 (extraM loXnDgL u4n5it )T3 preload( Extra long unit)

Preload T 0 30

3 preload 30

25 25

-0.1

20 20

-0.2

30 40 50 60 70 80 90 100 15 15

High accuracy running performance is realized Traveling distance mm 10 10

5 5

without major change of machine or device design ( 1 )

! 0 0

0 10 000 20 000 30 000 40 000 0 10 000 20 000 30 000 40 000

Note( 1) Position of the slide unit mounting hole is changed. Load N Load N

1N=0.102kgf=0.2248lbs.

Ⅰ-29 1mm=0.03937inch Ⅰ-30

300 mm 300 mm

Running deflection μm Running deflection μm

Basic dynamic load rating N

Displacement μm

Basic static load rating N

Displacement μm

Page17

2011.07.09 初校 CAT-1552-1 Ⅰ25-50

Models and Size Variations ④

C-Lube Linear Roller Way Super MX Features

MX Special raceway processing suppresses miniscule running deflection and

Master grade 1 significantly reduces pulsation compared to standard extra long units.

Fluctuation comparison data

Pulsation: Refers to the running deflection related to movement of the

rolling elements within the Linear Roller Way. Measuring method

0.1

Introducing the low fluctuation specifiication

0.08

product, for superb high-precision feed!

0.06 About 90% less

The C-Lube Linear Roller Way Super MX low fluctuation specifiication MX Master

Grade has special precision processing on the roller raceway surface, significantly 0.04

reducing fluctuation compared to the standard extra long unit and thus making it the About 50% less

0.02

ideal product for ultra-precision working machine shaft guides, which require Measures the vertical

runout when the table

high-precision, high-quality machining. 0

MXD35 MXDG35 MXDL35 MXDL35 is moved.

Standard unit Long unit Extra long unit Extra long unit

(Low fluctuation specifiications)

Super low fluctuation is achieved!

About 50% less fluctuation compared with the standard extra long unit!

2 Low fluctuation makes it ideal for ultra-precision working machine

shaft guides, which require high-precision, high-quality machining.

Fluctuation data

0.5 0.05

0.04

0.3 0.03

0.0090μm(9.0nm)

0.02

0.1 0.01

0

-0.1 -0.01

-0.02

-0.3 -0.03

-0.04

-0.5 -0.05

0 50 100 150 80 90 100 110 120

Distance (mm) Distance (mm)

The running deflection value is within 0.0090μm(9.0nm) in actual measurement!

Improve machining quality with the use of MX Master Grade!

3 The extra long unit contributes to improved load

Applicable products capacity and rigidity in mechanical equipment.

Series C-Lube Linear Roller Way Super MX Standard Elastic deformation relative to load is low in comparison

with the standard and long types, device rigidity is

Supported models MXL、MXDL、MXSL、MXNL、MXNSL improved, accuracy is improved, and resonance can be

Long

Size 30・35・45・55 avoided.

MX Master Grade (low fluctuation specifiications) is a special order

product; if needed please contact IKO. Extra long

Ⅰ-31 Ⅰ-32

Running deflection [μm]

Running deflection [μm]

Running deflection [μm]

Page18

Features of Special Environment Linear Way and Linear Roller Way

2011.07.09 初校 CAT-1552-1 Ⅰ25-50

Features of Special Environment Linear Way and Linear Roller Way ①

's unique ideas and experiences are utilized to explore new world for

special environment applications.

IKO Linear Way and Linear Roller Way are available for various special environment by using different

materials and grease, surface treatment and dust protection measures, etc. Typical application fields and

major countermeasures are described below.

Cllean Enviironment Clean Corrosion resistance

When the Linear Way or Linear Roller Way is used in clean ○ LCL Linear Way and Linear Roller Way ○ Hybrid C-Lube Linear Way L

environment such as a clean room, it is required that the ○ Precision cleaning and clean packaging ○ Non-magnetic stainless Linear Roller Way Super X

environment is not polluted by dust-generation by the Linear

Way or Linear Roller Way and it must have excellent rust ○ Stainless Linear Way and Linear Roller Way ○ Stainless Linear Way and Linear Roller Way

prevention property as rust prevention oil cannot be used. ● Black chrome surface treatment ● Black chrome surface treatment

● Specified grease (CG2 or CGL grease)

i ◇ Fluorine grease

Vacuum Environment

When the Linear Way or Linear Roller Way is used in vacuum

environment, it is required that the gas discharged from the Vacuum Heat resistance

Linear Way or Linear Roller Way does not pollute the environment ○ LCL Linear Way and Linear Roller Way ● Stainless steel end plate

or reduce the degree of vacuum, and it must have excellent rust ○ Precision cleaning and clean packaging ● Special environment seal

prevention property as rust prevention oil cannot be used.

● No end seal ◇ High temperature grease

● Stainless steel end plate

Heat Resiistance Measures ◇ Fluorine grease

When the Linear Way is used in an environment where

temperature is higher than usual, heat resistance of synthetic Foreign substances (wood chips and metal powder, etc.) Spatter

resin components and metal parts will be an issue.

○ Linear Way H Ultra seal specification ● Scrapers

○ Track rail mounting from bottom ● Caps for rail mounting holes (aluminum alloy)

● Double end seals ● Rail cover sheet

Dust Protectiion ● Scrapers ● Fluorine black chrome surface treatment

● C-Wiper ● Stainless steel end plate

If dust such as metal or wooden chips get into the way of the ● Caps for rail mounting holes

Linear Way or Linear Roller Way, reduction of life and

accuracy may be caused. Therefore, measures to prevent ● Rail cover plate for track rail

foreign substances from entering into the way are necessary. ● Rail cover sheet

● Female threads for bellows

● Specific bellows

Spatter Protectiion ○ Linear motion rolling guide series for special environment :

Spatter of welding, etc. is so hot that i t adheres to Collective name of linear motion rolling guide series models corresponding to special environment.

components. Foreign substances adhering to the track rail ● Special specification for special environment :

firmly cannot be fully removed by normal dust protection Special specification corresponding to special environment by combination of linear motion rolling guide series.

measures, so measures to avoid adherence and enhanced ◇ Lubricant :

foreign substances removal measures are necessary. Lubricant suitable for each special environment can be selected.

Ⅰ-33 Ⅰ-34

Page19

2011.07.09 初校 CAT-1552-1 Ⅰ25-50

Features of Special Environment Linear Way and Linear Roller Way ②

LCL Linear Way and Linear Roller Way

Neither grease nor oil Performance

World's first Liquid Crystal Lubricant Load durability (room temperature) Load durability (high temperature)

Liquid Crystal Lubricants are completely different from greases composed of base oils and thickeners.

Finished (without lubrication failure) Liquid

Liquid Crystal Lubricants are composed only of liquid crystal compounds, forming a new type Liquid Liquid crystal 4,136

of lubricant never seen before. Conventional grease base oils lubricate using dissimilar molecules, crystal 37,000 crystal 58,000 lubricant

lubricant lubricant Fluorine

causing difficulties with adhesion to metal surfaces and evaporation. Liquid Crystal Lubricant forms grease 683

Running

molecular aggregates, improving adhesion to metal surfaces and minimizing evaporation. The Liquid Finished when all

MAC-based lubrication looses

vacuum

Crystal Lubricant used in the LCL Linear Way and Linear Roller Way is the world's first Liquid Crystal 1,327 effectiveness

Fluorine Fluorine grease

Lubricant for bearings, achieving excellent lubrication functionality even under high contact pressure grease 495 grease 234 Lithium

soap base

during rolling contact and successfully creating revolutionary new functions. 1,730

grease

0 10,000 20,000 30,000 40,000 0 10,000 20,000 30,000 40,000 50,000 60,000 0 1,000 2,000 3,000 4,000 5,000

■Liquid crystal lubricant Liquid crystal molecules

structure Traveling distance (km) Traveling distance (km) Traveling distance (km)

Liquid crystal

molecules orient to

face the same direction Test Model number: LWL9…B Test Model number: LRXD20SL Test Model number: LWLF18…B Speed: 1m/s Temperature: 120℃

and form an aggregate conditions ① Speed: 1m/s Load: 181N conditions ② Speed: 1m/s Load: 2340N conditions Load: 114N Evaluation: Traveling distance until lubrication failure

Sliding conformity

Hydrocarbon chain with

the same structure as

the lubricant Outgas properties Low dust-generation properties

Difficult for molecules Ion intensity (A) 100℃ Ion intensity (A)

to separate (evaporate) 200℃

Metal surface due to strong Liquid

intermolecular forces 1.E-02 1.E-02 crystal

Grease molecular state Liquid crystal lubricant lubricant

molecular state 1.E-04 1.E-04 Low dust-

generation

grease CG2

Features 1.E-06 1.E-06 MAC-based

vacuum

grease

1.E-08 1.E-08 Lithium

Superiior lload durabiilliity soap base

grease

1.E-10 1.E-10

0 20 40 60 80 100 120 140 160 180 200 0 20 40 60 80 100 120 140 160 180 200 0 0.2 0.4 0.6 0.8 1 1.2

Long-term durability exceeds 70 times that of uorine grease at room Mass (M/e) Mass (M/e) Dust generation ratio

temperature and atmospheric pressure. Measuring Test Model number: LWL9・・B/N Load: 80N Speed: 1m/s

Vacuum level: 10-5Pa Conditions: Liquid crystal lubricant only

conditions conditions Evaluation time: 30 hrs Measured particle size: 0.5μm or more

2 to 6 times greater durability than other types of grease, even in

high-temperature environments.

Rolling resistance Evaporation characteristics

Superiior llow dustt-generattiion properttiies 2.0 Lubricant 60

1.8 [Kinematic Liquid

viscosity] 50 crystal

1.6 100

Fluorine lubricant

Dust generation is less than 1/10 of lithium soap based grease. 1.4 grease

1.2 [220mm2/s] 40 Fluorine

Lithium soap grease 100

1.0 base grease 30

Excellllent outgas propertiies 0.8 [220mm2/s] MAC-based

20 vacuum 92.3

0.6 Low dust-

generation grease

0.4 grease

0.2 [103mm2/s] 10 Lithium

soap base

The outgassing characteristics in high vacuum environments show 85.2

Liquid grease

0.0

excellent performance even even at high temperatures. 0 100 200 300 400 500 crystal 0

0 100 200 300 400 500 70 80 90 100

lubricant

Speed (mm/s) Speed (mm/s) Residual mass (%)

Miiniimiizes llubriicant evaporatiion Test T

Model number: LWL9・・

est Test Environment: Open atmosphere

B/N Model number: LRXSG20

conditions conditions conditions Temperature: 100℃ Time: 770 hours

Zero mass loss even at 100°C. Liquid crystal lubricants have no loss ● Applicable products

due to evaporation. Remark 1. Applicable for stainless steel models from each series.

・ Linear Way L Series Remark 2. LCL Linear Ways and Linear Roller Ways are

Liight and smooth slliidiing ・ Linear Way E Series individually made to order.

Compatible If needed, please contact IKO.

series ・ Linear Way H Series

・ Linear Way F Series

The rolling resistance is lower than that of uorine grease or lithium ・ Linear Roller Way Super X Series

soap-based grease.

Ⅰ-35 Ⅰ-36

Rolling resistance (N)

Page20

2011.07.09 初校 CAT-1552-1 Ⅰ25-50

Features of Special Environment Linear Way and Linear Roller Way ③

Hybrid C-Lube Linear Way ML

ML···/HB

While maintenance free performance of C-Lube Linear Way

ML is maintained, the silicon nitride ceramics ball improves

high-speed performance and reduces noise level. Performance

Ceramics has more resistance to deformation and more

rigidity than bearing steel and stainless steel. More than three times durability Noise reduction by about 4.5 dB

Slide unit High-speed performance Low decibel

Casing 50

■ Standard specification C-Lube C-Lube Linear Way ML

C-Lube Hybrid

Casing Martensitic stainless steel Ball Linear Way ML Damaged 45

C-Lube Linear Way ML

Track rail Martensitic stainless steel End plate 40

Ball Silicon nitride ceramics Grease nipple Interruption 35

Capillary lubricating element Hybrid

C-Lube End seal C-Lube

(Porous resin) Linear Way ML 30

Track rail

25

0 1 2 3 4 10 100

Features Durability life comparison Feed velocity m/min

Test conditions Model : ML12 Velocity: 300 m/min Acceleration: 40 G Test conditions Model : ML12 Measurement velocity: 30, 60, 90 m/min

Superriiorr hiigh--speed perrfforrmance … More than three times durability Small deformation of rolling Low preload reduction volume and

elements and excellent rigidity accuracy maintained after operation

High rigidity Abrasion resistance

12

Noiise reducttiion ……… Noise reduction by about 4.5 dB C-Lube Linear Way ML

10 Hybrid C-Lube

C-Lube Linear Way ML Linear Way ML

8

About

6

Hybrid 1/4

Hiigh riigiidiitty ………Displacement volume reduced by about 10% 4 C-Lube

Linear Way ML

2

0 0.25 0.5 0.75 1 1.25

0

0 500 1000 Preload reduction volume comparison

Load N

Superriiorr abrrasiion rresiisttance … Preload reduction volume is about one fourth Test conditions Model : ML12 Velocity: 300 m/min

Test conditions Model : ML12 Preload: Standard Preload Load direction: Downward Acceleration: 40 G Traveling distance: 13,000 km

※ All of the above based on comparison with our C-Lube Linear Way ML

+ Basic performance of C-Lube Linear Way

Achieved long term maintenance free Achieved light and smooth sliding

Maintenance free Maintenance free Sliding characteristic

Achieved long term maintenance free 100 3.0

No pre-packed grease ML9 Standard preload

No applied load

80 ML9

Eco-friendly Compact Smooth ML12

ML15

2.0

Minimized lubrication oil consumption Integral lubrication parts Excellent sliding characteristic 60

40

1.0

20

0 0

0 20 000km 40 000 60 000 80 000 100 000 0 50 100 150

Traveling distance km Traveling distance mm

1N=0.102kgf=0.2248lbs.

Ⅰ-37 1mm=0.03937inch Ⅰ-38

Lubrication oil supply amount wt% Displacement μm

Frictional resistance N Noise level dB(A)